Basic HTML Version

MAST I T I S CONTROL

SPRING 2014 ISSUE

LIVESTOCK MATTERS

18

‘

‘In almost every respect, things are easier,’

says Mr Wooldridge. ‘Calvings are easier,

there's almost no milk fever, milking is faster,

cows are under less metabolic stress and

they're far more likely to get in calf.

‘Profitability is far better too, with no yield

drop from mastitis, and antibiotic tube use

down by 70 per cent,’ he says.

‘Instead of spending money treating problems,

we are preventing them,’ adds James. ‘In fact

we've almost forgotten what to do when we

get a sick cow.’

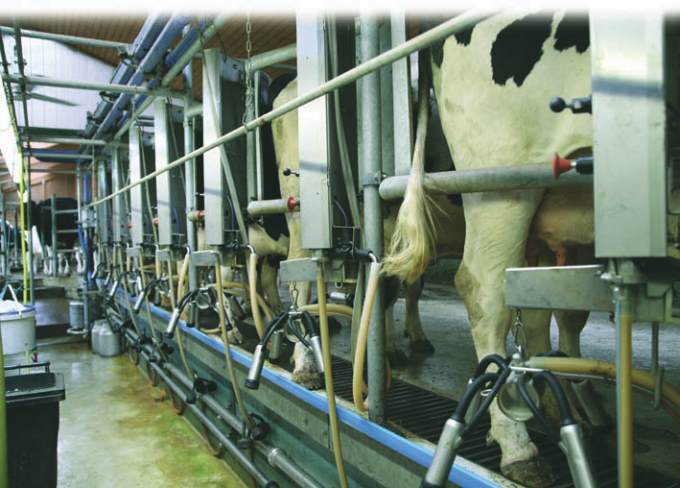

As part of the plan, the parlour routine has

also changed which today includes drying

off the 9,000 litre herd at slightly lower

production and having a better routine for

the process.

‘Previously we would have just administered

dry cow therapy in the parlour during milking,

but there was so much going on that we were

not properly focused on the job,’ says James.

‘Now we bring the group back in after

the parlour has been washed, teat-dip

with surgical spirit, use a dry cow tube

where necessary and seal all the teats,’

he says.

Today, mastitis rates are running around 40

cases per 100 cows per year and as the

plan is reviewed, attention moves to new

areas that will further the downward trend.

This includes improved cleanliness and access

to drinking water, increased frequency of

scraping and improved gateways and farm

tracks using oolitic limestone.

‘Now we're finding it's the small things,’

says James. ‘Some seem really picky but if we

can do 100 small things better we can get

the incidence lower still and I can't see why

we couldn't achieve 20 cases per 100 cows

per year.

‘Whatever effort we have put in has given us

something back and that motivates us to keep

on going,’ he adds. ‘Once you start getting

the milk back it becomes a lot easier - they

calve in well and yield well so everything

becomes more interesting.’

From a vet’s perspective, Sean Hughes adds:

‘The plan has led the team into other areas

such as calf and colostrum management

which has given them better calves and better

replacement heifers.

‘The great thing about the plan is it provides

the evidence to point you in the right direction

and without it they may not have had the

confidence to invest in the shed and they

could have gone on for years and not

achieved improvement.

‘But this isn’t just about the plan,’ Sean insists.

‘These are highly motivated people who have

engaged and want to improve. That's why

there has been such dramatic improvement.’

The DairyCo Mastitis Control Plan

Stage

Process

On this farm

Stage one:

analysis and diagnosis

Milk records are used to analyse cell

counts. Initial and recurrent mastitis cases

are recorded and plotted graphically.

On Martin Wooldridge's farm, clinical

mastitis had risen to 120 cases/100

cows/year, with most cases shown to be

of dry period origin.

Stage three:

monitoring

The results of any actions are monitored on

an ongoing basis to ensure improvements are

made and sustained.

This herd has reduced mastitis cases to 40

cases/100 cows/year; a target of 20 cases

is considered realistic and antibiotic use has

been cut by 70 per cent.

Stage two:

the questionnaire

The farm's vet or consultant asks questions

and observes processes to complete the

questionnaire. Actions are identified which

must, should or could be undertaken.

Improvements made included a switch from

straw to sand for dry cow bedding; improved

dry cow nutrition; improved drying off routine

and limestone gateways and tracks. Cubicles

are being installed for dry cows.

You can check with your vet if your XLVets practice delivers the plan or

e-mail

mastitiscontrol@dairyco.ahbd.org.uk