Basic HTML Version

LIVESTOCK MATTERS

16

SUMMER 2013 ISSUE

CASE STUDY

Increased milk production

Prior to the robot installation, milk yields

were averaging 9,300 litres. Now this

has risen to 10,300 litres.

Mark explains: ‘The robot’s computer

reports show more cows are reaching

a decent peak, and yields have

better persistency.

‘Submissive cows are yielding up to

3,000 litres more in a lactation, as a

result of not standing in the yard waiting

to be milked, and less stress as they can

choose when they go to get milked and

avoid the bullying from dominant cows.

So these timid cows now have the

opportunity to fulfil their potential.’

The partial mixed ration that the cows

have free access to is composed of grass

and maize silages, molassed sugar beet

feed, brewers grain, molasses and a 24%

crude protein blend. Mark adds: ‘The

feed rate per litre is no different - so with

better forage next year, we think they will

be even more efficient.’

Mastitis control

Reductions in mastitis cases are common

after moving onto automatic milking

systems as cows are getting milked more

frequently. At Cross Hill Farm, cell counts

have dropped from around 200,000

cells/ml to 140,000 cells/ml.

Methods of mastitis control have had to

change. Mark explains: ‘In the parlour,

we’d tube the problem teat, and inject

an antibiotic.’

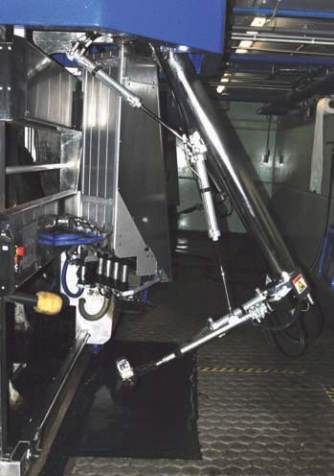

The robot system detects blood levels in

the milk, conductivity, and on a quarter by

quarter basis, the percentage of yield that

is obtained versus expected. These three

measurements are used to identify when

mastitis treatment is needed.

Ian explains: ‘This data analysis enables

mastitis cases to be identified sooner, and

the Robinsons have found a reduction in

treatments required.’

Mark says: ‘Once a mastitic cow has

been flagged up on the computer, we

walk through the herd, find the cow,

and give her the antibiotic injection in

the cubicle. Repeat offenders do get wise

to this, and have been known to get up

and move when they see you coming

with the needle!’

Lameness control

Lameness is kept under control by having

a footbath in the crossovers at the end

of the shed.

Additionally, the Robinsons are considering

installing rubber mats on the slats by the

milking units. Ian explains: ‘Cows are

turning as they enter and exit the robot.

If there are other cows around then these

turns can be exacerbated, and can

increase the incidence of white line

lesions. Rubber can reduce the shearing

force exerted on the foot, reducing

incidence of this type of lameness.’

The next steps

There are some decisions ahead for the

Robinsons to make due to a large batch

of replacement heifers coming through.

Ian explains: ‘If the herd increases, then

cows will come to the unit less frequently,

so there’s no gain in milk output. So we

will be looking at the milking records and

evaluating whether to cull some of the

slower milkers, and replace them with

faster milking heifers - albeit they will

be lower yielding than some of the

older cows.’

At Cross Hill Farm, the robot system has

improved cow health, increased yields

and freed up a significant amount of time

for Mark and his father. They recommend

that farmers considering a move to robotic

milking should look at different systems on

different farms, and check out the local

dealer, as good back-up is essential.

Getting started

At Cross Hill Farm, the main calving period is

from May to October and so the contract with

the robot manufacturer was that the machines

had to be operational by then. That way,

heifers calving down would be introduced

straight onto the robot system.

Having been involved early on in the decision

to change the system, Ian was able to ensure

that heifers were ready to calve in May:

‘Once the decision was made the Robinsons

pushed the heifers’ growth rates to get them to

the right size for service as early as possible.

They then channelled a lot of effort into heat

detection. We did a lot of PD sessions to

detect those not in-calf, so we could focus on

smaller numbers as time went on.’

At the start, the herd numbered 200 cows,

as the Robinsons wanted to get both the cows

and themselves, used to the system. Now, a

year on, the herd has expanded to 230 cows.

Ian adds: ‘If there are plans to expand the

herd, then it’s important to account for this in

the initial set-up design, and have the wiring

ready, otherwise it’s an expensive process to

add an extra robot at a later date.

Mark comments: ‘We thought it would be

much harder to start with than it actually was.

The first week we worked in shifts 24/7. But

within two weeks, it had settled and we were

saving 35 hours each week.’