Basic HTML Version

HEAT DETECT ION

AUTUMN 2013 ISSUE

LIVESTOCK MATTERS

24

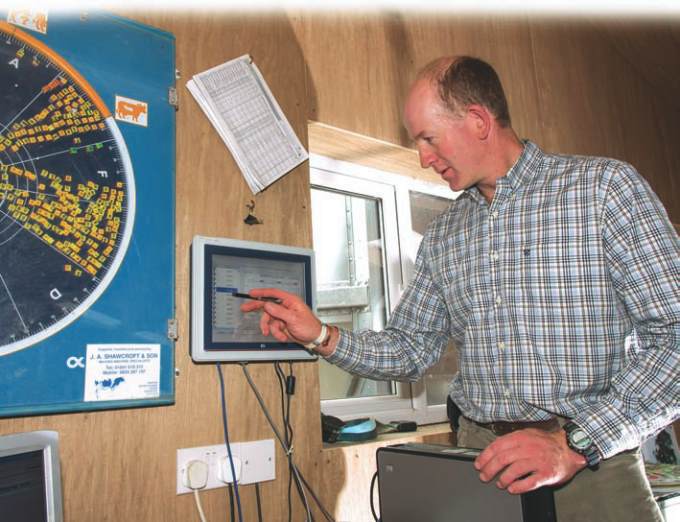

One producer who has embraced the

technology and improved fertility, mainly

through more accurate heat detection, is

Shropshire producer Tim Downes. He’s

recently shifted the calving pattern of his 250

cross bred organic herd from two blocks to

one spring 12-week period.

‘This is really a lifestyle choice,’ says Tim who

farms with his father and wife Louise ‘It suits

our farm and growing season too. But the

success of our system relies on getting cows in

calf, and picking up heats is vital. We can’t

really catch up if we miss serving cows.’

This was the reasoning behind Tim’s initial

interest in the electronic heat detection system

Silent Herdsman. ‘We took the plunge and

bought it two years ago. All cows were fitted

with the collar with its transponder that

downloads movement information wirelessly

to the PC monitor.’

Improvements in submission and pregnancy

rates have been monitored. ‘We serve cows

from May 1 to the end of July and by early

August this year we’d PD’ed two thirds of

cows and 85.5% of them were in calf,’

adds Tim.

Overall fertility is improving as planned at

The Farm at Longnor with the calving to first

service interval at 68 days, an improvement

of 14 days in 12 months, and conception

rate to first service up 10% to just over 54%.

First service submission rate is now 75%.

As well as good results, Tim has improved the

system further by installing a segregation gate

that directs cows as they leave the parlour

depending whether they are on heat. Regular

updates to the parlour software that ‘speaks’

to the gate means that it knows which cows

to ‘syphon’ off. ‘It’s far less stressful for the

cows and easier for us.’

While staff still note bulling cows manually

when they see them, Tim knows they are

monitoring activity far more accurately with a

sophisticated electronic system. ‘But it also

flags up those with reduced activity. ‘Quiet’

cows and any abnormal patterns in behaviour

also get onto our radar.’

Tim’s vet, James Marsden from Shropshire

Farm Vets, is a true convert to electronic heat

detection. ‘The benefits really come to the

forefront in Tim’s herd where the aim is to get

as many cows as possible to calve in the first

three weeks of the calving season.’ Two

factors affect this; the submission rate then the

conception rate,’ he says. ‘Conception rates

rely on many factors such as body condition,

nutrition, health and timing of service. But the

submission rate is solely dependent on heat

detection - the better the heat detection, the

better submission rate.’

James is in no doubt that the access to 24/7

activity data and being able to pick up

patterns from Tim’s Silent Herdsman is playing

a major part in picking up more heats and

helping to avoid mis-timed AI, and its

associated problems.

‘Excellent heat detection is a prerequisite of

progressive dairy farming,’ adds James.

‘Heats must be picked up throughout the

day and night and abnormalities sorted out

quickly. Proven electronic systems can do this;

it is certainly helping Tim achieve an even

shorter calving period, which in turn plays its

part in easier herd management, better health

and welfare for the herd and more profit on

the bottom line.’

Tim Downes using his heat detection system

Tim Downes’ cows