Basic HTML Version

LIVESTOCK MATTERS

16

AUTUMN 2013 ISSUE

MAST I T I S FEATURE

In August 2012, there was a sharp rise in

clinical cases. Adrian raised the issue with

Jonathan on one of his fortnightly fertility visits.

An investigation followed; bacteriology tests

revealed the pathogens behind the mastitis

were those found in the environment - E.coli,

and Strep. uberis.

Adrian also mentioned to Jonathan that for a

long time he had wondered why his cows

had ‘warty’ teat ends, which were apparent

as the clusters came off.

Jonathan explains: ‘This is due to a build-up

of keratin around the tip of the teat - called

hyperkeratosis. It’s caused by the milking

process - it can affect teat closure and also

creates an environment in which bacteria can

inhabit. This makes the cow more susceptible

to mastitis infection from environmental

pathogens, and in turn can lead to higher

cell counts.’

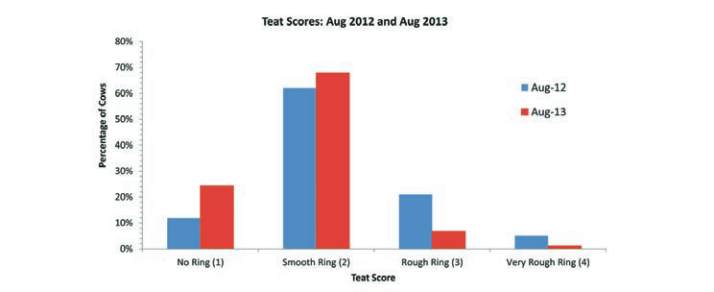

So the first step was to assess the scale of

the problem: one of Jonathan’s Kingsway

colleagues visited during a milking and

carried out some teat-end scoring. As each

cluster came off, the ends of the teats were

scored for how smooth or rough they were

on a scale of 1 to 4.

The scores highlighted there was a significant

problem of hyperkeratosis, as cows were

being over-milked. Alterations to the milking

machine set-up were needed. So Adrian

called in his dairy engineer.

Previously, the milk flow threshold for cut-off

was 200ml/min - this has been increased to

400ml/min. And the take-off time has been

reduced so clusters come off quicker once

milk-out has ceased. To help the cows adjust

to the different timings, these changes were

made gradually, with the engineer visiting

three times over a 10-week period.

Jonathan explains: ‘With a flow rate setting of

400ml/min, the cows are being milked for a

shorter time - but it doesn’t mean yield is

being lost. It does mean there’s less pulling on

the teat, less damage, and ultimately less

opportunity for bacteria to invade the teat.’

‘Sometimes, when parlours are upgraded the

system can revert to factory settings. So it’s a

good idea to always check the settings after

any alterations are made.’

The new settings have made a dramatic

difference to teat condition, with very few

‘warty’ teats occurring now (see graph).

The percentage of teats which are in good

condition - a score of 1 or 2 - has risen from

74% to 92%.

At the same time, Adrian also changed his

procedures for teat preparation. He had been

using an iodine-based spray for pre and

post-milking. But then switched to a foam dip

pre-milking, followed by a barrier dip with a

high level of emollients, for post-milking.

Adrian adds: ‘The foam dip is more

expensive than spraying, and not as quick,

but it contains ingredients beneficial for

teat repair.’

Jonathan adds: ‘Not only does teat condition

have an impact on milk hygiene, but it also

reduces milking time as teats are easier to

prepare, and cows are more comfortable.’

With the progress made this year in reducing

cell counts, Adrian has now stopped

disinfecting clusters in-between cows: ‘We

have saved a bit of time in doing this, but

obviously the dipping takes longer so at the

end of the day, we are about evens.’

He adds: ‘For several years now, cows with

higher cell counts have been milked last. This

all helps reduce the risk of cross-contamination

in the parlour.’

Altering milking machine

set-up

Adrian sums it up: ‘We used to get

around 100 mastitis cases per 100

cows per year. By culling out the high

cell count cows and using a teat sealant,

it reduced to around 60 cases. By

introducing peracetic acid, cases

dropped to 45 per 100 cows per year.

‘In the past 6 months, thanks to alterations

to the milking machine set-up, and

perhaps the introduction of the foam dip,

we are now running at around 35 cases

of mastitis per 100 cows per year. I just

wish I’d mentioned the warty teat-ends

a bit sooner!’

Jonathan adds: ‘I make fortnightly routine

fertility visits for many of my dairy clients.

But I’m not just there to PD cows. It’s a

great opportunity to talk about other

aspects of herd health and production,

some of which may not require a special

call-out and can be sorted quite quickly.

So my advice to any farmer who has

noticed something a bit different is to just

run it by your vet when he next visits, you

never know how much it could save you!’

Better and better

Hyperkeratinisation

Teat Scores for Adrian Beresford

Foam dip

Cluster removal