Basic HTML Version

WI SCONS IN TOUR

SPRING 2012 ISSUE

LIVESTOCK MATTERS

12

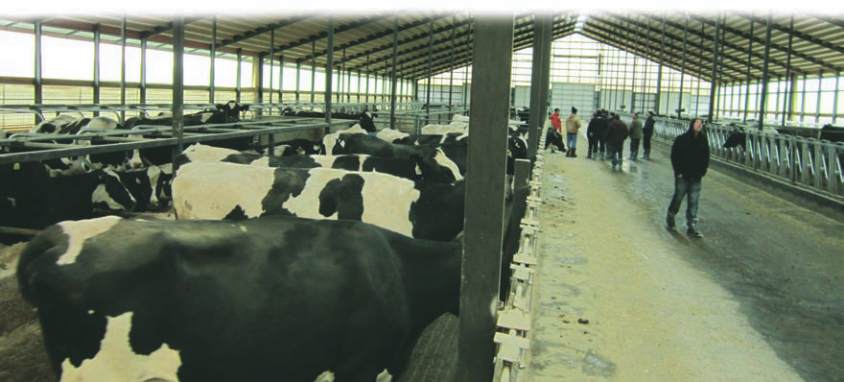

Case Study:

Larson Acres

This business has expanded from 1,000

cows - completed in 2010 to include a

new mechanically cross ventilated 234

x 1,166 feet dry cow and transition barn

on sand cubicles for 1,200 cows with a

second 44 point rapid exit milking parlour.

The cross-vented barn system involves a

sealed unit with extraction fans running

along the whole length of one side of the

building. To ensure adequate movement of

air, relatively small inlets are made along

the far side of the building to move air at

400ft per minute, which equates to 60

air changes per hour in the summer.

Temperatures commonly reach 40 o C in

the summer and the main aim of investing

in such an expensive ventilation system

is to avoid heat stress.

While we never see the same extremes

of temperature in Yorkshire, cows housed

inside during the summer are still at risk.

Dairy cows are affected by heat stress at

lower levels of heat or humidity than those

that would begin to bother humans.

Cross-venting was an extreme solution

but more attention to achieving fresh air

in our buildings was one message we

took from our trip.

Larson Acres had also invested a huge

amount of capital in their slurry handling

system which comprised a three-stage

separation system - sand laden slurry from

cows passes through housed separation

lanes and drum filters to produce sand

which is drained and re-used, and solids

(fibrous, high phosphate, 40 t/day, stored

up to one month); the sludge from this

process passes into a screw press

producing a liquid used directly on alfalfa

crops between silage cuts or passes into

a membrane filter to produce liquid

permeate (1% dry matter, contains half the

initial nitrogen level and no P or K, used

for growing crop application. This system

allows a precision nutrient management

plan to be implemented with P & K added

back as required by each crop.

Whether the amount of capital invested at

Larson Acres is the right business approach

or not, this farm believed strongly in taking

a lead on promoting the positive impact of

dairy farming and its sustainability in terms

of animal health, environmental impact and

place in the community.

In common with the majority of the farms

we visited they had converted to sand

cubicles. The downside is handling the

slurry and the farms we visited had

employed a range of methods to overcome

these problems. The bigger farms were

recycling sand which represented a huge

saving as very little additional sand needed

to be purchased per annum. Mechanical

separation was the most expensive option

and technical issues on some farms resulted

in sand of questionable cleanliness. Flume

and separation lanes were impressive and

produced very clean sand from a very

grand but ultimately simple system.

l

Attention to detail

As these farms had expanded, the attention to

detail had not been lost. In some cases it may

even have been enhanced as people could

be given more focused jobs developing a

degree of specialisation. Forage management,

hygiene and consistency in all daily tasks

were a common factor. As the herds had

grown they had taken control of every

important detail.

I finished the tour very encouraged that

the best of our dairy industry is just as

advanced and talented as that in

Wisconsin. Our group certainly took the

chance to review the platform that they

have for further growth and what the

limiting factors on herd performance might

be. The yields achieved by many of the

farms we visited were impressive; over 50

litres per cow per day on one farm. The

temptation might be to explain this as the

result of the exceptional forage base,

feeds like bloodmeal and additives/

treatments such as Monensin/BST and

doubtless all these things are part of the

story. More important though were the

common factors of exceptional attention

to detail, a focus on cow comfort and

a robust staff structure where everyone

knew their role.

UK vs. USA

THE FACT S

Herd size:

2,900 cows

Staff:

11 family and 42 employees

Average yield:

30,000lb +

Key Points:

l

Clear role definition can be the

difference between stressed,

under-performing staff and a solid

team which is easier to manage and

recruit into.

l

Produce good protocols and enforce

them through a clear staff structure.

l

Excellent results can be achieved

on all systems but sand probably

delivers the best results at a given

level of management.

l

Think about how we are perceived

by our customers and what our role

in our communities is or should be,

this could be more and more

important in the future.

l

If you want to progress identify your

own limiting factor.

l

Step back and define your business

and the roles within it - even if you

currently fulfil most of them yourself

at the moment!

Kindly supported by Landskills in Yorkshire and Humber

Crimped maize

Cross Vented barn

Mechanical sand separation